- Denise project

- Sealine Gupco project

- Zohr project

- Moheshkhali project

- Moho Nord project

- Tanap project

- DESFA Aliveri-Stefani Project

- Aramco LTA project

- COOEC in Qatar

- COOEC in Nigeria

- Bul Hanine Re-Development Project

- Pipe Layer Barge Israfil Huseynov

Resinex was one of the first manufacturers of pipe deployment floats in the world.

Since the earliest 90’s, more than 2000 pieces have been produced for the major projects of pipelaying of the world. Resinex, as a matter of fact, has supplied various types of floats for the most important jobs in this field: Denise (Egypt), Hasdrubal (Tunisia), El Burullus (Egypt), LTA Aramco- Saipem (Saudi Arabia), Sealine Gupco (Egypt), Dragon Cigma Export Pipeline (Venezuela), Moho Nord (Congo), Zohr (Egypt), Tanap (Turkey), Moheshkhali Floating LNG (Bangladesh), DESFA Aliveri-Stefani (Greece), Pipe Layer Barge Israfil Huseynov (Azerbaijan), Bul Hanine Redevelopment (Qatar) and many others.

One of the most considerable supply has been to COOEC, which in turn supplied Dangote Oil Refining Company (Nigeria) and Qatar Petroleum.

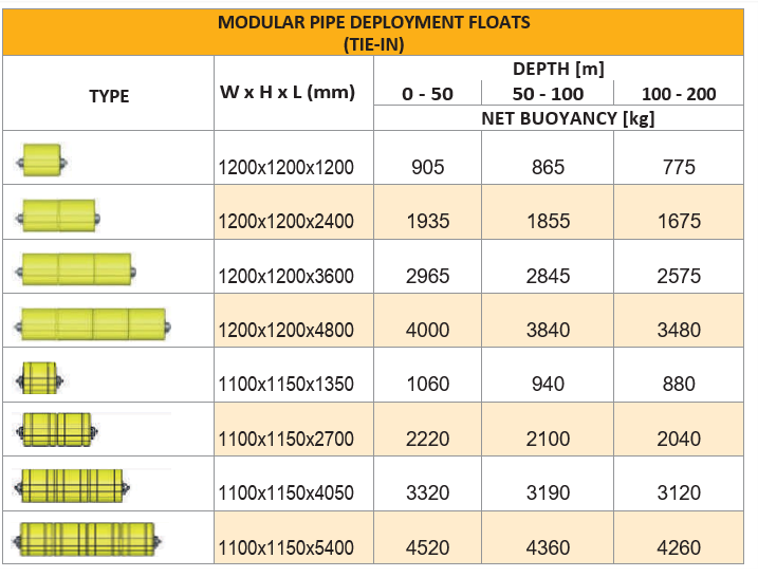

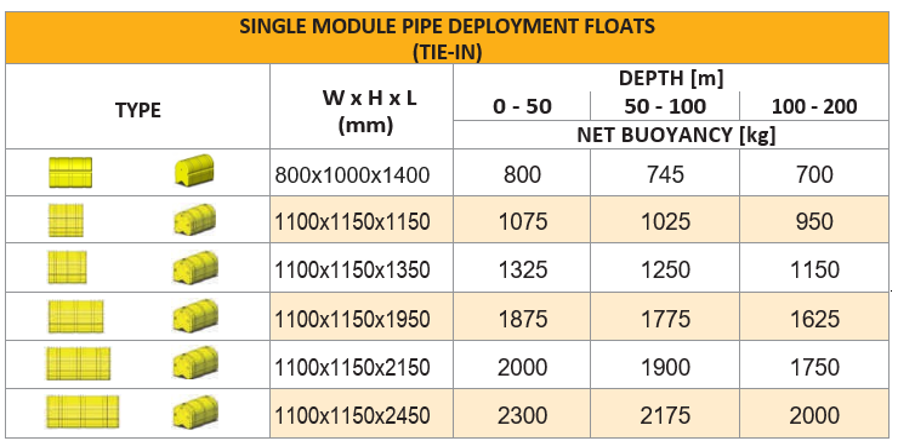

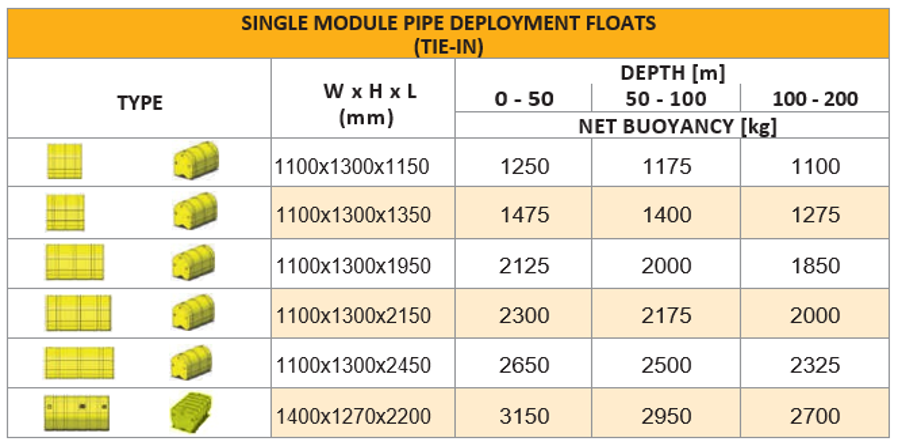

The secret of Resinex lies in its wide range able to adapt to the most assorted needs of clients creating a tailor-made product. Range goes from 800 kg to 3000 kg of net buoyancy for each single module which can be combined to reach 5000 kg and more. They are usually utilized from 10 to 200-300 m of depth, but if necessary higher depths can be reched.

Thanks to the modularity of the single modules, it is possible to combine them in order to make buoys with different buoyancies.

Although tie-in floats manufacturing procedure is long and complex, Resinex is able to produce a high quantity of modules in a short time.

The particular concave “V” shape of the lower part, has been specifically designed to limit the pipe mobility and to ease the operation phases reducing time and costs of the operations.

There are some different types of installation which require the usage of the floats to position the pipes underwater.

One of the main installation ways of the pipelines, in which the usage of the floats is needed, is the Shore Pull. It consists in positioning the pipe with the floats in shallow water near the coast; then the pipe is pulled from the bottom and the friction that happens on the seabed is reduced thanks to the presence of the floats which make it much lighter in the water.

Resinex flexibility has been really appreciated by the big offshore operators, such as Saipem, Technip, Petroleum Marine Services, Snamprogetti, Sapura Energy and others. Details of buoys and fixing procedures have been chosen accordingly with them.

After the completion of the deployment operations of the pipelines, regarding the release systems, Resinex has developed together with its clients, also with experimental tests on a real scale, diverse manners which adapt to the features of each project.

Buoys can be fixed on the pipes with different types of strap according to the operational necessity: steel strap, steel and textile strap, special plastic material strap.

The release can take place under water through the usage of a ROV (Remotely Operated Vehicles) or through dive specialist operators who work to release the fixing system; alternately quick release systems have been studied which allow to activate quick release hooks directly from a service boat.

The reliability of Resinex is guaranteed by the continuous tests made at Resinex Marine Research Centre in Adro (Brescia) which are: Impact tests (1), Fit up tests (2), Release tests (3), Pressure tests (4), Buoyancy tests (5).

- Impact test

- Fit up test

- Release test

- Pressure test

- Buoyancy test