In the installations for open sea oil activities and, more in general, for all the installations for the transfer and storage of hydrocarbons, including the various phases of loading and offloading of the tankers, the safety standards must be of the up most and with the highest attention paid to the environment. With this in mind, the floating systems are chosen by the oil companies with the greatest care so as to satisfy the most severe and rigid criteria in order to guarantee the safety of the costly FSO (Floating, Storage and Offloading), FPSO (Floating, Production, Storage and Offloading) and the brand new FDPSO (Floating, Drilling, Production, Storage and Offloading) systems. Among the Resinex customers, they have always naturally been the major companies engaged in the hydrocarbon field.

In the installations for open sea oil activities and, more in general, for all the installations for the transfer and storage of hydrocarbons, including the various phases of loading and offloading of the tankers, the safety standards must be of the up most and with the highest attention paid to the environment. With this in mind, the floating systems are chosen by the oil companies with the greatest care so as to satisfy the most severe and rigid criteria in order to guarantee the safety of the costly FSO (Floating, Storage and Offloading), FPSO (Floating, Production, Storage and Offloading) and the brand new FDPSO (Floating, Drilling, Production, Storage and Offloading) systems. Among the Resinex customers, they have always naturally been the major companies engaged in the hydrocarbon field.

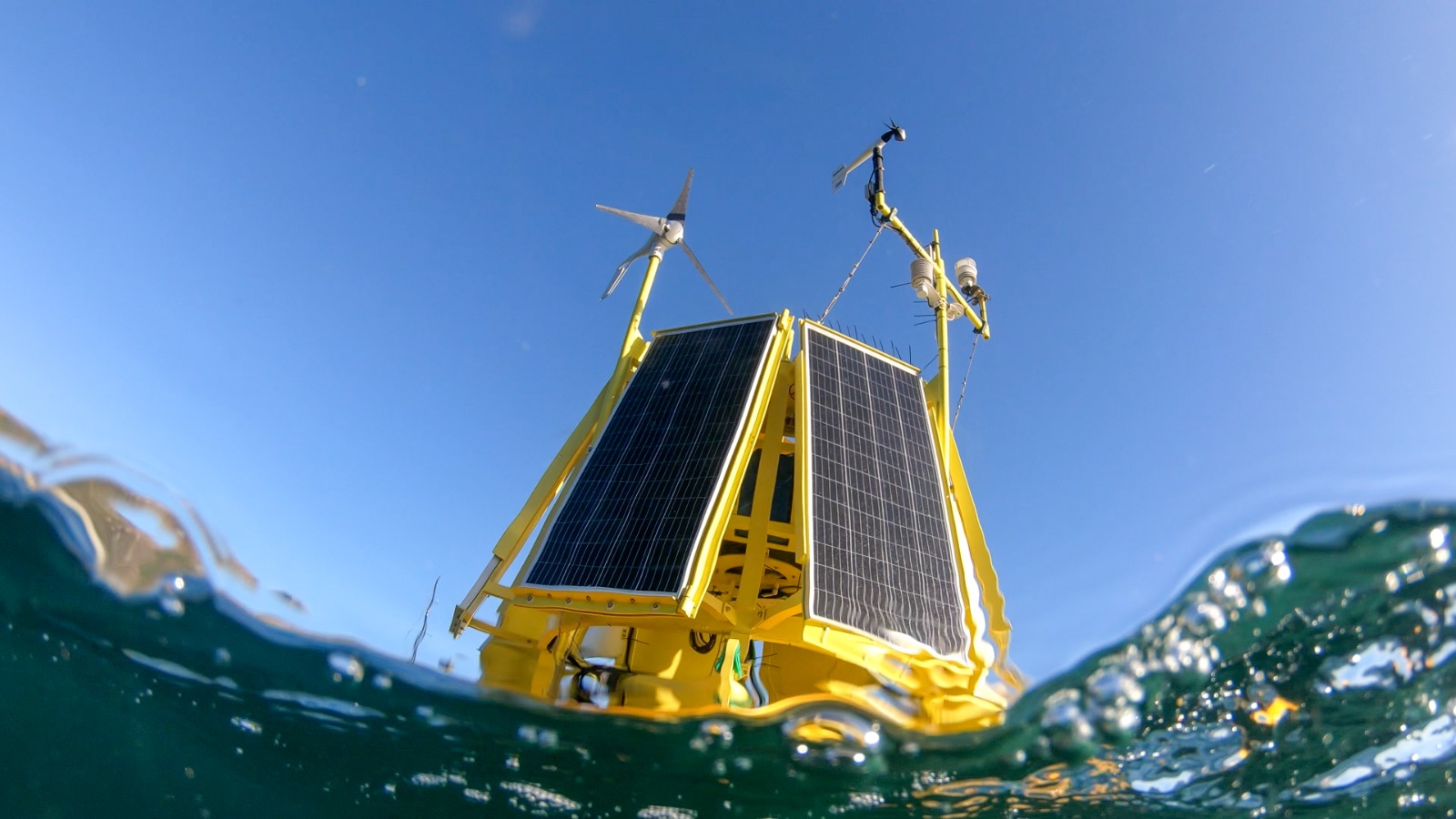

An important consignment was that made to the Tunisian company Pireco, in which our company delivered the entire maritime signalling system (Pharos Marine) for the El Bibane platform situated off the coast of the states North African coast. The consignment consisted of five lanterns which show the morse letter “U” (++-) and of a horn which emits the same signal acoustically. This is all controlled by a control panel.

The signalization, light and acoustic, is of a type projected and studied for the use in hazardous areas of hydrocarbon extraction. It is resistant to high temperatures and is completely autonomous both for the main and reserve units and at the same conforming to the Imo norms and Aism-Iala recommendations.

Staying in the oil sector, 50 Resinex tie-in floating modules (specifically projected with a cavity for piping support and tested for use at depths of 150 metres) and 40 arrows, for cables were consigned to Saipem for the Denise Egyptian project, where a 32-inches pipe was laid to the platform situated in the Denise Pliocene gas field, about 60 kilometres off the Egyptian coast at a depth of about 85 metres.

The Sonlis, a logistics company of Sonagol, the Angolan state oil company, and SBM Imodco bought other Resinex support elastic buoys for use in the African plants. Also the Sonsub Company of the Saipem group, specialized in maritime exploration and owners of ships and ROV (Remotely Operated Vehicles) uses Resinex products as floating systems for the deep water support for the cutting of the pipes without crew (DWCM).

But Resinex not only supplies buoys in plastic: for customers used to more traditional products, we still also manufacture big steel floats such as those which Chevron positioned in its African operations with a net buoyancy of 15 tons.