Resinex proves itself as leader of big moorings for large oil and gas tankers.

The huge oil and gas tankers need to have multi-buoy moorings safe and easy to operate.

After the positive experiences in Angola, Albania, Cameroon, Malaysia, Italy, Spain, Indonesia,

Mozambique, Azerbaijan, United Arab Emirates, Malta, Montenegro, Yemen, Saudi Arabia and Venezuela, Resinex was called again to supply a Conventional Buoy Mooring (CBM) to the Egyptian company EPPC, main producer of propylene and polypropylene of the North African country.

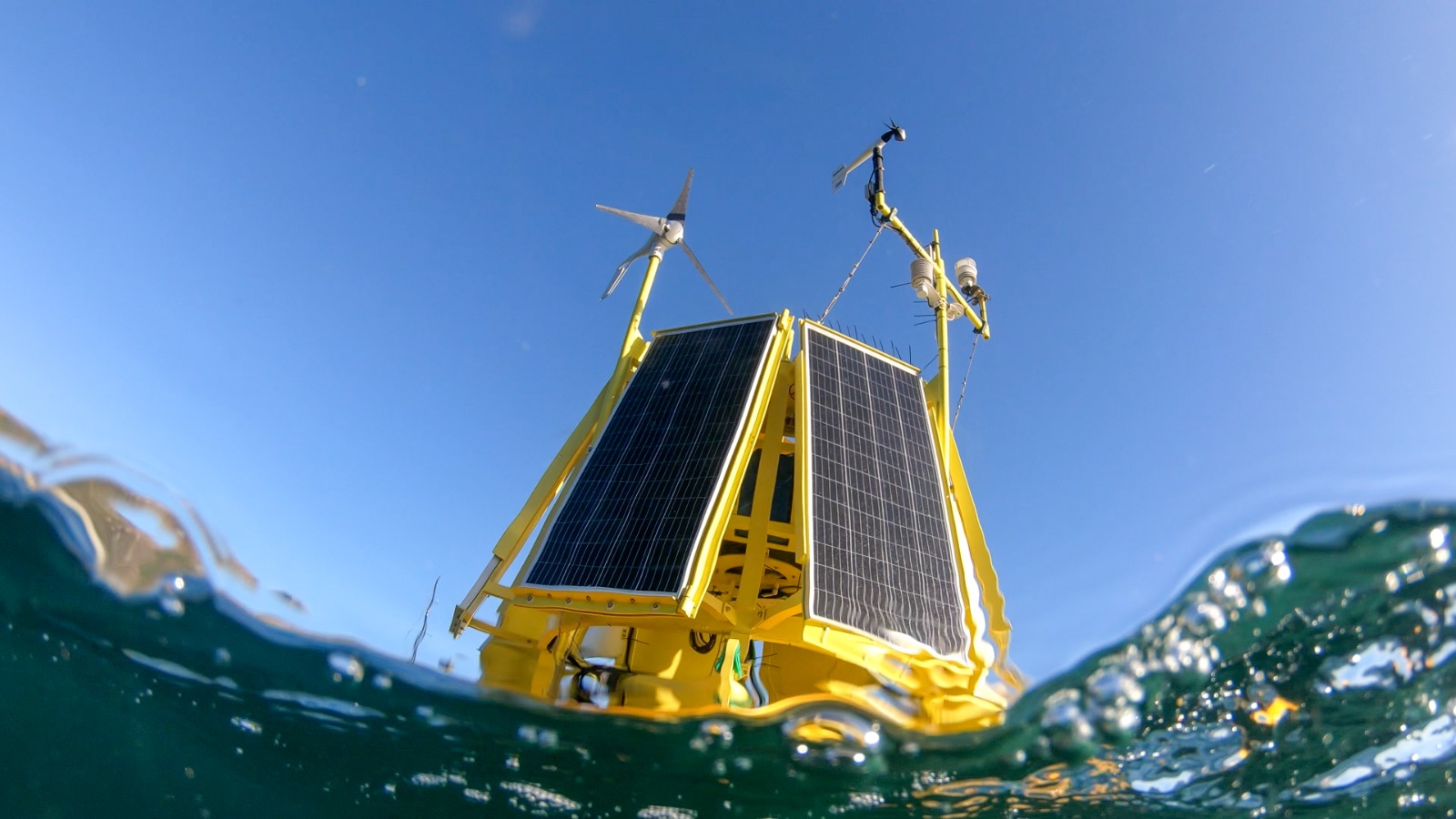

In this case, 6 big modular buoys type PEM 50 catamaran buoys were projected, supplied and assembled.

The PEM 50 buoys are modular, in plastic, with a diameter of 5 m, a height of 2,2 m and a net buoyancy of 28 T.

Resinex has been called upon to supply a Conventional Buoy Mooring (CBM) for the Egyptian company EPPC, the largest producer of propylene and polypropylene in the North African country.

These buoys are equipped with the exceptional system type Resinex MLS (Multi Lever System), which assures the stability of the buoy even during the strong tensions of the vessel mooring.

All the six buoys are also provided with Quick Release Hooks (QRH) type Straatman with remote control system powered by solar system and batteries. Each buoy is complete of two QRHs of 90 T.

As all the big Resinex buoys, even the PEM 50 are modular (16 plastic modules per buoy), thus: unsinkable, with minimal maintenance costs and easy to be carried.

Seven days were enough for Resinex engineers to arrange the assembly at Port Said and to perform the final test.

The Egyptian company Maridive, national leader in maritime and offshore operations, handled the installation and the mooring of the buoys to the seabed through the use of six anchors type Stevpris MK6 High Holding Power.

Check out the video of the installation: https://youtu.be/VTIyCiAwcIw

- Buoy Catamaran for EPPC

- Buoy Catamaran for EPPC

- Buoy Catamaran for EPPC

- Buoy Catamaran for EPPC

- Buoy Catamaran for EPPC

- Buoy Catamaran for EPPC