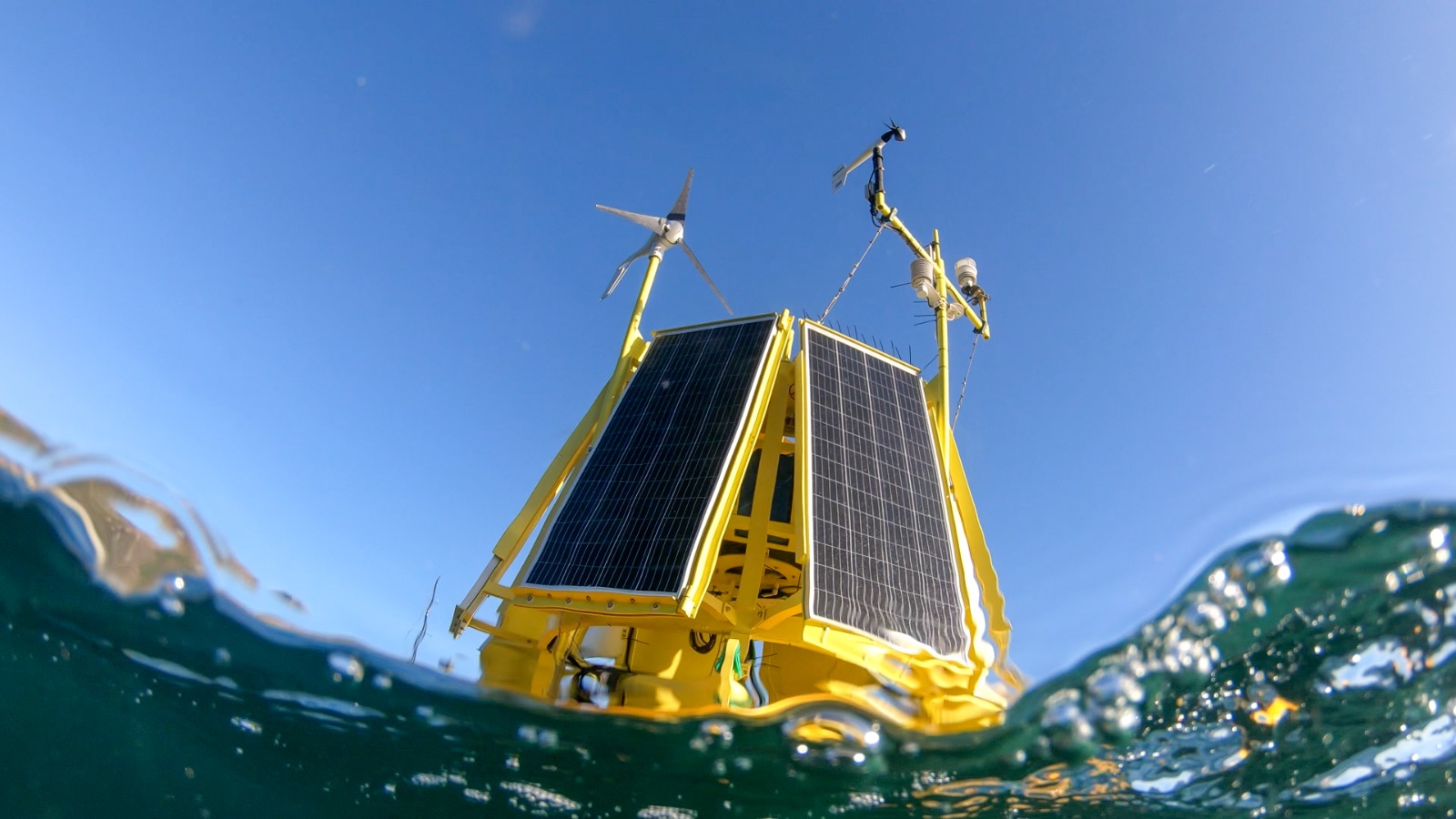

Way back in 1991, Resinex manufactured the largest plastic buoy ever made in the world until that moment: a deep-water buoy with a diameter of 4.3 m, height of 10 m, a nett buoyancy of 72 tons and an operational depth of 60 meters.

It was commissioned by Ugland Offshore and shipped to Norway to the Statfjord B Field, operated by the Norwegian state-owned energy company Statoil (now Equinor).

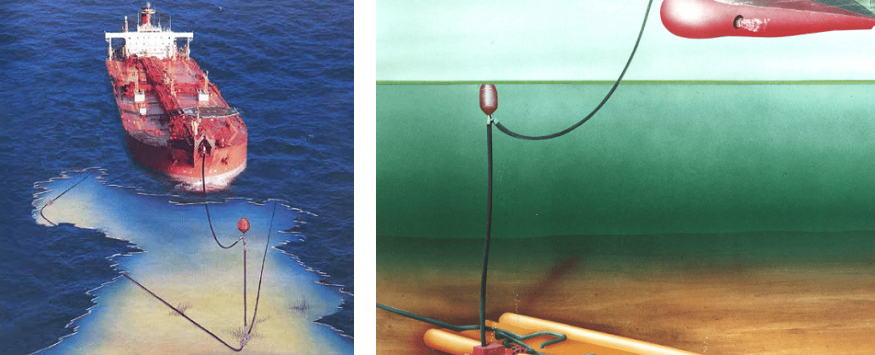

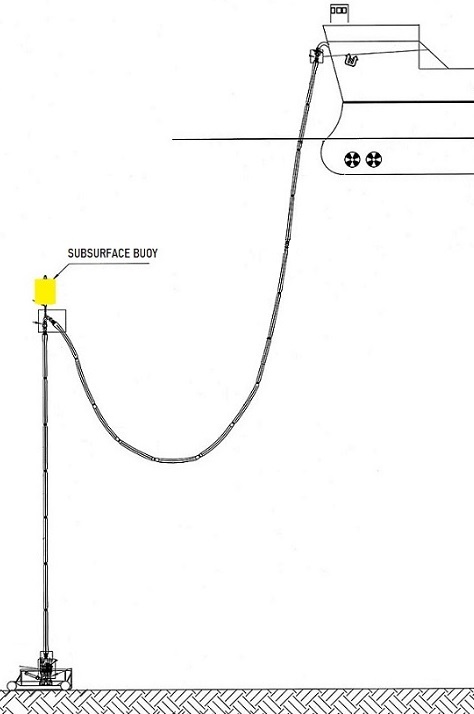

Composed of 42 modular sections made of ultra-high-density polyurethane foam, it was part of the innovative UKOLS, a subsurface oil loading system consisting of a flexible oil loading line leading from an oil rig storage tank on the seabed, held vertically in tension at a depth of 60 m by the Resinex PEM 43 buoy.

30 years ago, this loading system represented a real innovation because it could be easily used by tankers without requiring mooring points. It replaced more expensive systems (with surface buoys) and eliminated the risk of collision or other inconveniences during the operations.

After exactly 30 years, we still recall this supply as one of the most significant of our activity.